Its applications, stretching from personalized goods to full-scale industrial manufacturing, showcase its vast potential.

Amidst the several facets of this technological marvel, this discussion centers on how large-scale 3D printing is gradually reshaping the industrial sector.

Pioneers In The Game: Leading 3D Printer Reviews

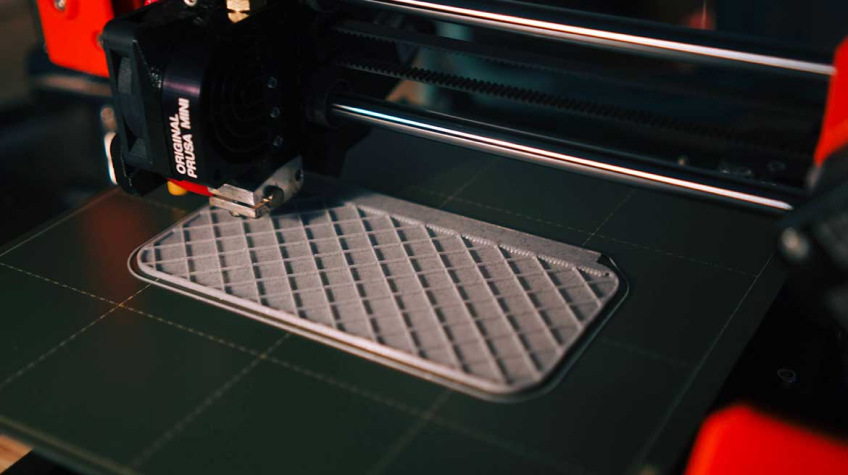

Delving into the vast world of 3D printing is an endeavor that often begins with understanding the machinery behind the magic.

Today, there are several 3D printers in the market, each boasting unique features tailored for different niches.

Review Of Creality CR-M4

Creality is no newcomer to the world of 3D printing. Their CR-M4 model, as reviewed by Clever Creations, is gaining traction for a variety of reasons.

Built for precision and durability, the CR-M4 is versatile, offering both beginners and seasoned users a balanced experience.

Its robust build plate and advanced nozzle mechanism ensure consistent printing, making it suitable for a variety of industrial applications.

Clever Creations highlighted its easy assembly and user-friendly interface, making the setup process a breeze even for those new to the realm of 3D printing.

While the review had its criticisms, the general consensus remains: the Creality CR-M4 is a significant contender in the industrial 3D printing arena.

Adapting To Industrial Needs

In the realm of industrial applications, not every 3D printer makes the cut.

The dynamics involve producing at larger scales, demanding consistent quality, and maintaining operational efficiency.

Printers like the CR-M4, with their robust build and precise printing capabilities, are increasingly finding their place in large-scale manufacturing units.

These printers offer scalable solutions, ensuring that as businesses grow, the machinery can adapt without compromising on quality.

Sustainability And Environmental Considerations

The increasing emphasis on sustainable manufacturing processes makes 3D printers like the CR-M4 invaluable.

With the capability to produce with minimal waste and the option to use eco-friendly materials, these printers contribute significantly to green manufacturing.

Moreover, the on-demand nature of 3D printing reduces surplus production, aligning with the principles of lean manufacturing and environmental stewardship.

The Art Of Design: Utilizing Free Vector Graphics In 3D Printing

Before one can print, there’s a paramount step: design. In 3D printing, this often involves digital blueprints, often represented as vector graphics.

Accessing A World Of Designs

Free vector graphics have democratized design access for 3D printing enthusiasts and professionals alike.

These repositories offer a plethora of designs, catering to a range of industrial applications.

From intricate components to large-scale prototypes, free vectors ensure that businesses don’t always have to start from scratch.

By simply downloading and tweaking existing designs, industries can significantly reduce design times and costs.

Customization At Its Best

While free vector graphics offer a starting point, the beauty of 3D printing lies in its customization.

Using these vectors as a base, industries can modify designs to suit specific needs.

Whether it’s adjusting the size, incorporating brand elements, or even merging multiple designs, the possibilities are endless.

Intellectual Property Considerations

Though the allure of free vector graphics is undeniable, it’s vital for industries to tread cautiously.

Intellectual property rights can often come into play, especially if designs are used for commercial purposes.

Industries must ensure they have the necessary permissions and are in compliance with any licensing agreements associated with the downloaded vector graphics.

Future Horizons: Next Steps For 3D Printing In Industry

As with any transformative technology, the journey of 3D printing is far from over. It’s a field ripe with potential, where innovations are constant, and the horizon perpetually expands.

Integration With AI And Machine Learning

The union of 3D printing with Artificial Intelligence (AI) and Machine Learning promises unprecedented advancements.

Predictive analytics can optimize designs for structural integrity, while AI-driven automation can streamline the entire production process.

Expanding Material Horizons

Today, industries aren’t just limited to plastic.

Research in 3D printing materials, from metals to organic compounds, is opening avenues for diverse applications, be it in aerospace, medicine, or fashion.

Democratizing Manufacturing

As 3D printing technology becomes more affordable and accessible, a shift in the manufacturing paradigm is anticipated.

From centralized factories to localized production hubs, the future might see a more decentralized, yet interconnected, global manufacturing landscape.

Redefining Speed And Precision: The Role Of 3d Printing In Rapid Prototyping

The ever-evolving dynamics of the market demand swift innovations. Businesses need to conceptualize, design, and test new products at an unprecedented pace.

This is where 3D printing intersects with rapid prototyping, offering solutions that are reshaping the prototype development process.

From Idea To Reality In Hours

Traditionally, prototyping a new product could take weeks or even months. With 3D printing, this timeline is drastically reduced.

Designers can now convert their digital sketches into tangible prototypes within hours.

This swift transformation from a digital concept to a physical model accelerates the iterative process, allowing for quick design modifications based on real-world testing.

Cost-Efficiency In Product Development

Rapid prototyping via 3D printing also introduces significant cost savings.

The direct manufacturing process reduces the need for molds, dies, and expensive tooling.

As a result, businesses, especially startups and SMEs, find it more feasible to experiment with designs without bearing the brunt of heavy initial investments.

Enhancing Stakeholder Communication

A tangible prototype serves as an effective communication tool.

Whether it’s investors, clients, or internal teams, a physical model can clearly convey design intent, functionality, and aesthetics.

3D printed prototypes ensure that all stakeholders can visualize, feel, and understand a product concept, bridging gaps and aligning visions.

Closing Regards

In conclusion, large-scale 3D printing is not just a technological advancement but a revolution in the making.

As industries embrace its potential, the way we design, produce, and even think about manufacturing stands to be redefined.